HEAT EXCHANGERS DIAGNOSTICS

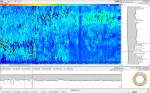

We provide comprehensive diagnostics of heat exchanger pipelines, including all the components – both carrying and connecting. The inspection focuses on the initial condition, and situation after a period in service. Pre-operation inspection is to record the initial condition. Comparison of inspection results after a certain period of service – either with the initial values, or values from two subsequent inspections, allows to establish the level of damage, and to predict the service life.

We are the most experienced, and regarding the capacities and knowledge the largest organisation offering pre-operation and operation inspections of heat exchangers using eddy current and magnetic flow methods in the Czech Republic. Tediko company uses its own know-how, top-notch equipment by renowned suppliers, and testing components made in-house. This enables maximum precision of the measurement results.

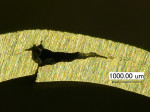

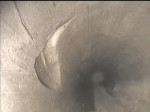

Apart from eddy current method (ET), magnetic bias eddy current method (ET-MB), remote field method (RFT), flux leakage method (MFL) and IRIS ultrasonic method other processes are applied – visual inspections including video endoscopes length up to 14 m, ultrasound thickness measuring, RT profilometry of tube wall thickness, positive material identification (PMI), or tightness inspection. Corrosion damage of all the components is examined.

|

|

|

|

|

|

|

|

|