UTT – WALL THICKNESS MEASURING

When measuring the wall thickness, we are after the minimum thickness of the material in a given point. We can measure thickness of products made from different materials, including plastics. As regards the devices equipped with memory, we can measure using pre-defined grids X, X-Y and X-Y-Z. These grids can be made in a chosen size, up to the device memory capacity. Thousands of points can be stored in the memory. With LCD displays it is possible to follow the course of echo, and check/optimise the settings. The saved points can be sent to PC and used further (statistics, maps and charts).

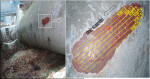

We use thickness gages that also allow continuous measuring in lines, so-called B-scans. In some cases we use our own manipulators-crawlers that enable measuring in otherwise inaccessible places.

|

|

|

|